Ground Thaw & Concrete Curing

Unbeatable for thawing frozen soil, concrete curing and de-icing of lines and equipment. Keep your crews and equipment working all winter long! Thaw frozen ground for excavation and concrete placements, cure concrete achieve required strength gain sooner, deliver your projects on time and stay on schedule.

CORE VALUES

We know that our clients’ operations depend on quick and reliable access to equipment. Super Sonic’s Equipment Rental program has been built to get you the equipment you need.

CONTACT FOR SERVICES

Mailing Address:

#201 111 Broadway Blvd

Sherwood Park AB T8H 2A8

Tel: 1 (780) 886-9954

Email: info@supersonicstucco.ca

Fuel Type: Diesel

Description

The E 1250 was designed with the safety features you require and the simple, intelligent operation you desire.

Engineered for reliable performance and trouble-free starts with large 74 gallon fuel tank for up to 115 hours of run time at 87% efficiency. With thawing capabilities of up to 2,500 sq. ft. of frozen ground at an average rate of one foot-deep per day*, the E 1250 will set, finish and cure 2,500 sq. ft. of concrete or up to 7,500 sq. ft. with accessories (standard model only).

Heating Power:

140,000 BTU/h

Capacity:

2,500 ft2 · Runtime: 90 h

Features:

- 1,250 ft of hose

- 87% heat efficiency

- 68 hours of run time (at 100%)

Applications:

Ground thaw, concrete curing

Fuel Type: Diesel

Description

With 3,000 ft. of hose and a hydraulic hose system, the E 3000 allows for single person set-up and placement, for greater flexibility on all applications.

The E3000 thaws or cures up to 6,000 sq. ft. With accessories this heater will cure up to 18,000 sq. ft. or provide 535,000 cu. ft. of dry heat at 83% efficiency, the highest in the industry. Several options are available including a 3kW or 6kW liquid-cooled diesel generator and lifting bail.

Heating Power:

385,000 BTU/h

Capacity:

6,000 ft2 · Runtime: 108 h

Features

- 3,000 ft of hose

- 87% heat efficiency

- 61 hours of run time (at 100%)

Applications:

Ground thaw, concrete curing

Fuel Type: Diesel

Description

The Fusion 1400 is a compact hydronic surface heat system for smaller projects. Heated hose can stay on the spool allowing smaller lengths to be applied to the site. Easily train users on this equipment with one touch-start capability. Thaw specific areas, and use during cold weather concrete warming/curing, pre-pour warming, and ground frost prevention. Light enough to be towed by a pickup.

Space Heating:

Up to 175,000 BTUs

Thaw Area:

Up to 2,800 sq. ft. (260 sq m)

Cure Area:

Up to 8,400 sq. ft. (optimal conditions slab on grade)

Features:

- Fuel Capacity: 100 Gal. (378.54 liters)

- Fuel Requirements: #1 Diesel Fuel

- Fuel Consumption: 1.25 GPH nozzle, 4.73 LPH without generator (at full operation)

- Boilers: One 210,000 Input BTU

- Operating Temp: 50oF – 190oF (10oC – 88oC)

- Boiler Efficiency: 87% (with fuel per-heater)

- Heat Transfer Fluid: 48 US gallons (181.70 liters)

- Space Heating: Up to 175,000 BTUs

- Thaw Area: Up to 2,800 sq. ft. (260 sq m)

- Cure Area: Up to 8,400 sq. ft. (780 sq m) (optimal conditions slab on grade)

Applications:

Ground thaw, concrete curing

Fuel Type: Diesel

Description

Portable surface heat system with multi-tasking ability. Efficiently thaw ground, heat, warm and cure concrete during cold weather. Prevent ground frost and maintain reliable performance throughout projects, even in extreme cold.

Space Heating:

Up to 234,000 BTUs

Thaw Area:

Up to 6,000 sq. ft. (557 sq m)

Cure Area:

Up to 18,000 sq. ft. (optimal conditions slab on grade)

Applications:

Ground thaw, concrete curing

Feautres:

- Fuel Capacity: 170 Gallons (644 liters)

- Fuel Requirements: #1 Diesel Fuel

- Fuel Consumption: 1.75 GPH burner nozzle, 6.63 LPH without generator (at full operation)

- Boilers: One 280,000 Input BTU

- Operating Temp: 50oF – 190oF (10oC – 88oC)

- Boiler Efficiency: 87% (with fuel per-heater)

- Heat Transfer Fluid: 80 US gallons (303 liters)

- Space Heating: Up to 234,000 BTUs

- Thaw Area: Up to 6,000 sq. ft.(557 sq m)

- Cure Area: Up to 18,000 sq. ft. (1,672 sq m) (optimal conditions slab on grade)

How It Works

Why Ground Heaters Are Best

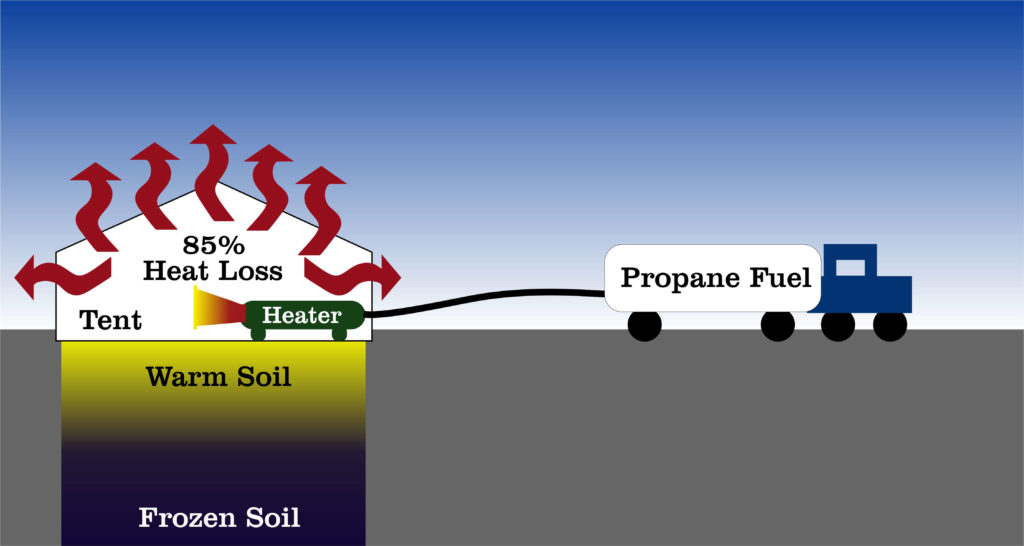

The Old Method: Hot Air

In the past, using propane heaters to warm the air was the only way to thaw ground. However, it has numerous important drawbacks:

- Limited thaw depth

- Requires building costly temporary enclosures

- Requires noisy propane heaters

- Creates outrageous propane bills

- Emits noxious fumes into enclosure

- Requires constant supervision

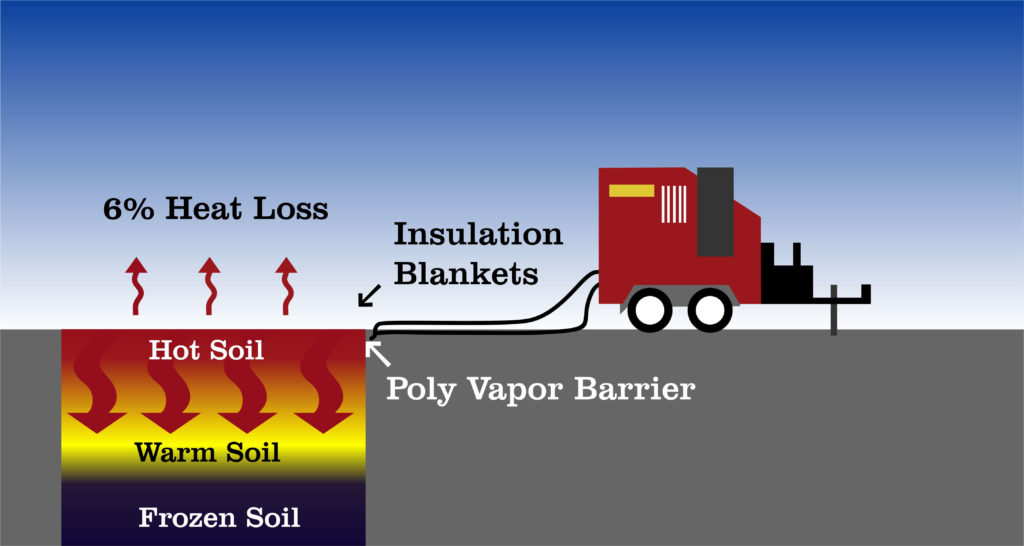

The Best Method: Ground Heater

Melting ice in soil requires 143 BTU/pound. Ground thaw heaters can heat the soil at a fast rate without requiring temporary enclosures to be built and with minimal supervision.

- Thaws at a fast rate typically 1 ft. deep per day

- Achieves up to 10′ thaw depth per application

- No temporary enclosure to build

- Uses fuel efficiently

- Requires minimal supervision

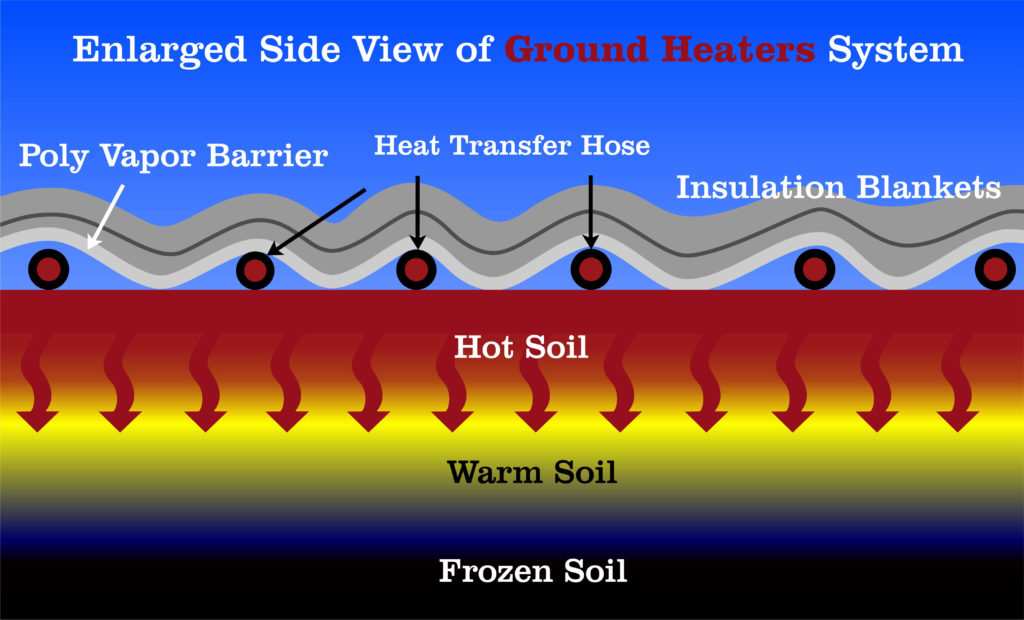

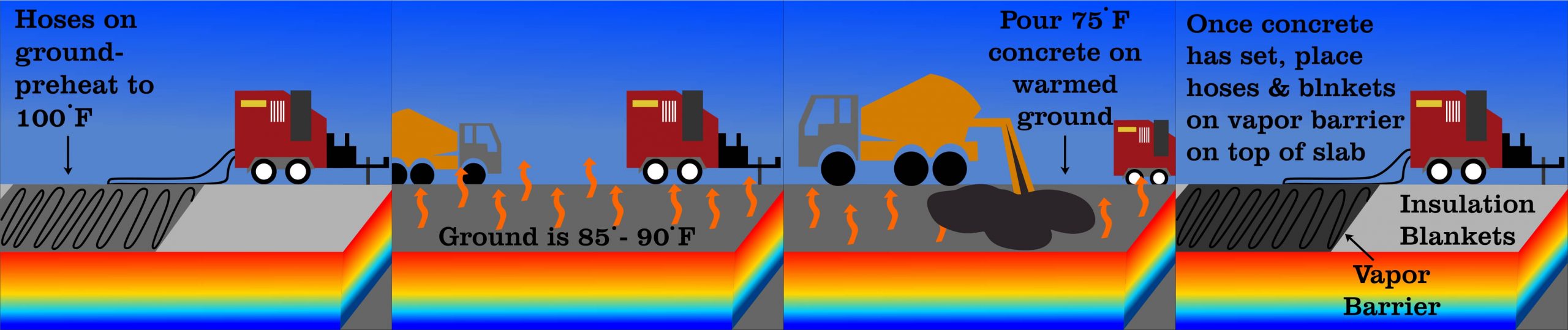

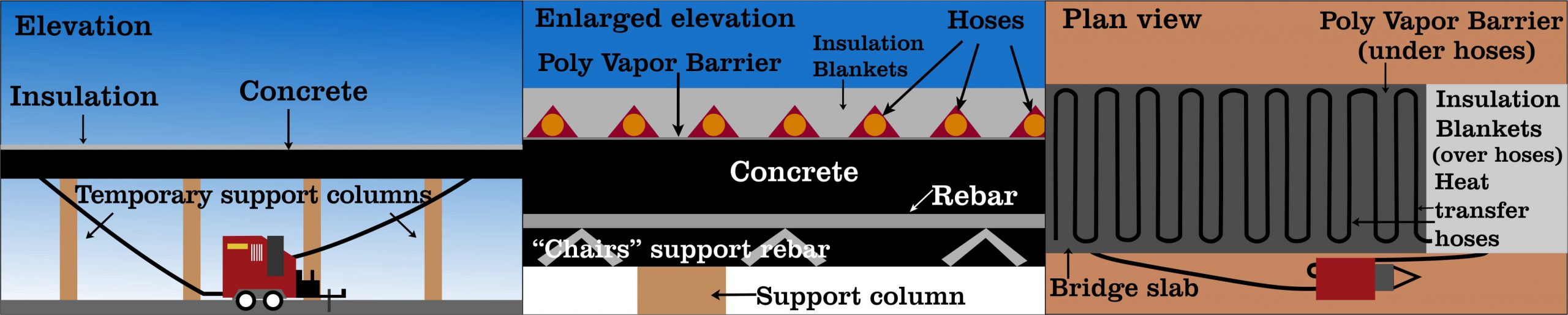

Ground Heater System Setup

- Prepare Site

Scrape snow and ice from thaw site. - Position Heat Transfer Hose

Space hose 2 feet on center over thaw site area. A closed system, only heat goes into ground. - Lay Poly Vapor Barrier

Place minimum 3 mil poly vapor barrier to contain water vapor.- Prevents loss of heat

- Keeps soil moist for better heat conduction

- Keeps hoses and blankets clean

- Place Insulation Blankets

Prevent heat loss and direct heat into ground. Requires 2 to 3 layers of high R value blankets.

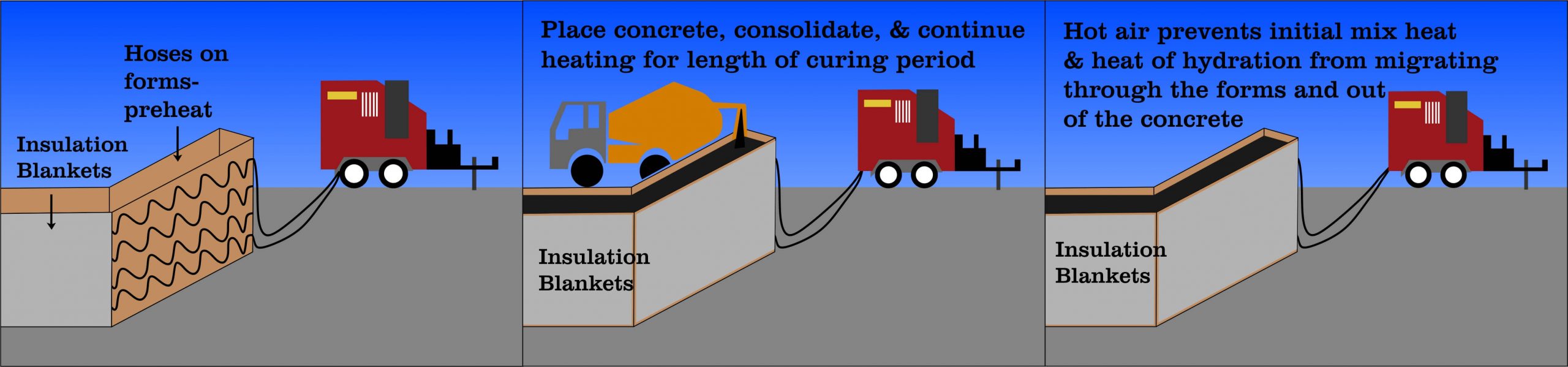

Slab On Grade

Elevated Slab

Poured Walls Or Columns